The Motorcycle Parts New Zealand Specialists Ideas

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Table of ContentsMotorcycle Parts New Zealand Specialists Things To Know Before You Get ThisWhat Does Motorcycle Parts New Zealand Specialists Mean?The Only Guide to Motorcycle Parts New Zealand SpecialistsThe Buzz on Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingThe Definitive Guide for Motorcycle Parts New Zealand SpecialistsSome Known Facts About Motorcycle Parts New Zealand Specialists.

So, connect to one of our professionals today.CNC machining innovation is promptly ending up being the focal factor of many different production processes around the globe as a direct outcome of its lots of advantages over various other techniques. In addition, the industries that produce motorbikes have actually obtained on board with this pattern. The most ingenious firms are now creating their engine elements and wheels making use of machining methods originally established for motorbike components.

You might be wondering why we make use of. Now that we have your attention allow us clarify the reasoning behind this contemporary growth in the motorcycle manufacturing market.

The 3-Minute Rule for Motorcycle Parts New Zealand Specialists

Furthermore, you have complete control over the appearance of the elements, even down to the minute details. Occasionally, motorcyclists may choose to fix up their experience by mounting aftermarket elements or changing the bike's transformation. Once once again, computer system numerical control (CNC) machining is one of the most functional technique. Upgrades may be of any kind and style you want.

Our Motorcycle Parts New Zealand Specialists PDFs

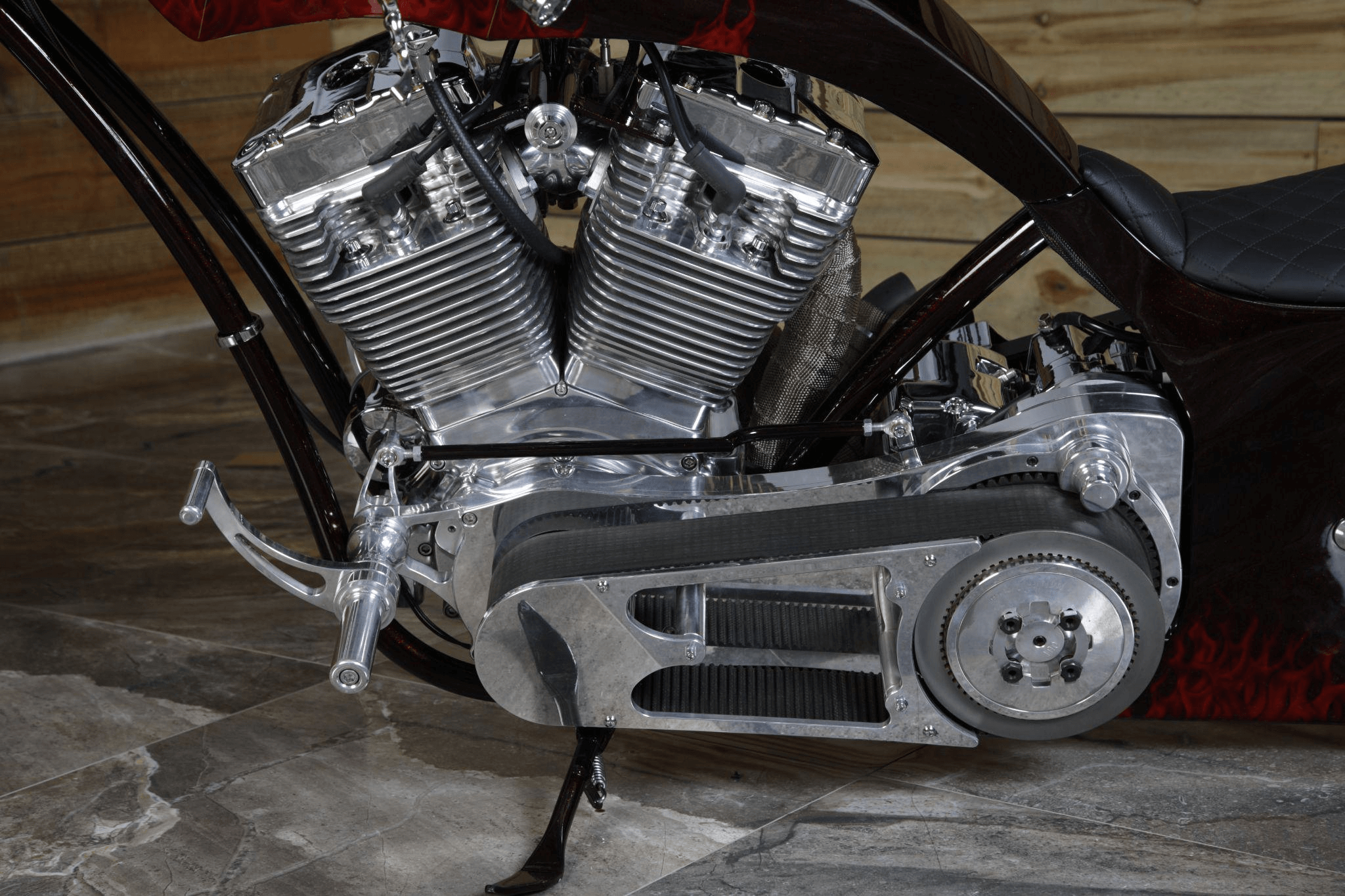

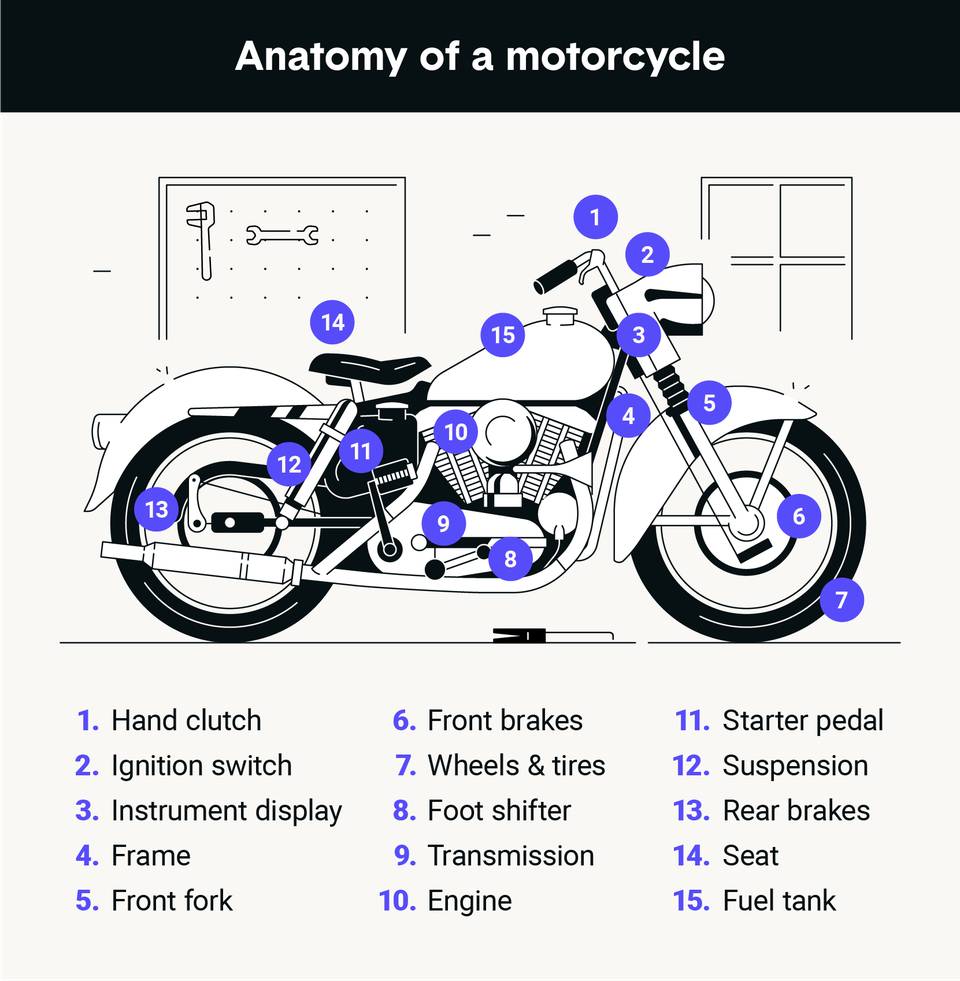

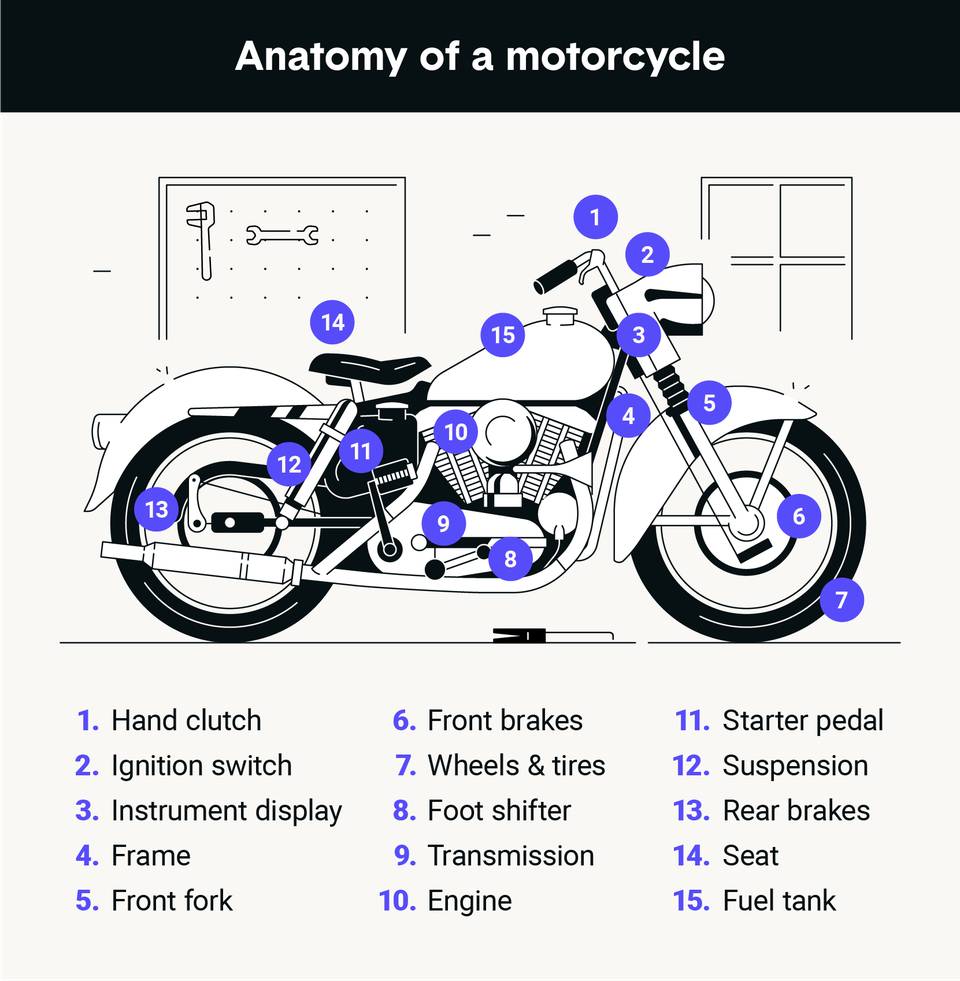

CNC machining might be utilized to make virtually all of a motorbike's steel and plastic components. To proceed, we'll discuss a number of machined components for motorcycles. Unlike those on automobiles, wheels on bikes have a tendency to be much more noticeable. As a result, the bike's appearances might be boosted with the appropriate modification of these wheels.

Milling procedures are utilized to obtain the desired degree of wheel modification. An additional facet of the bike that might be individualized is the tires.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

When it comes to a vehicle (or a motorbike), one of the most vital part is the engine. A number of individuals point to it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be elaborate and call for designs with a high level of precision.

Illumination is another complicated aspect of personalization. Use only top quality things, nevertheless, given that these lights are essential for the safety and security of motorcyclists and other motorists or people on the roadway, especially during the night. Motorbike fronts lights have three primary components: the bulb, or light source, the lens, and the real estate. Particularly, we tailor the lens and the housing.

Milling processes with a remarkable surface would lead to the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the various other hand, is not made up of breakable materials; rather, it is built out of hard polymers that can be machined right into even more elaborate patterns.

An Unbiased View of Motorcycle Parts New Zealand Specialists

They frequently have fancy geometries with a wealth of min information. Motorcycle makers often cast these components, but just for the production of bespoke parts. However, CNC machining is the technique of choice when generating special pieces. visit the website Machining on five axes in today's globe is the means through which any layout shape might be recognized.

The success of the procedure is contingent on the mill cutters' capacity to compute subtle and difficult angles properly. Select Runsom for your customized bike components! We have the capability to produce difficult and stylish elements making your motorbike incomparable. A lot of are crafted from light weight aluminum or steel alloys, each of which has its uses and benefits.

Right here are a couple of instances of steels commonly made use of in motorbike element machining. Light weight aluminum is the key product made use of by firms specializing in creating customized motorbike elements to produce the majority of these parts. In the past, we would develop our engines out of cast iron. On the other hand, aluminum is quickly becoming the product of choice, partly due to the fact that it is more lightweight.

Zinc refers to an additional steel that is very light in weight and has excellent machining top qualities due to its high mechanical toughness. This material may be created into almost any kind of shape and maintains its measurements well. Even mission-critical parts that need a high degree of accuracy might take advantage of their use.

All about Motorcycle Parts New Zealand Specialists

An additional metal that sees heavy use in the manufacturing of CNC-customized components is magnesium. It is amongst the lightest metals that are now obtainable and has exceptional machinability functions and strength commensurate with its reduced weight. Among the downsides of magnesium is that its dirt might quickly ignite.

As a result of its exceptional machinability and weldability, stainless steel is an alloy that is particularly well-suited for CNC processes. Along with this, they have terrific rust resistance and a high visual appeal. Their most common usage in creating Resources different motorbike components is bolts, such as screws and screws. Their low susceptibility to oxidation and deterioration makes them excellent for this usage.

Some Of Motorcycle Parts New Zealand Specialists

It seems that CNC transforming and grating are the fundamental processes. Nevertheless, alternate methods exist, such as drilling. Let's explore most of these machining techniques extensive. The CNC transforming technique is taken into consideration a subtractive production method. Furthermore, it needs maintaining bars of product, frequently plastic or steel, in placement and get redirected here after that twisting a cutting device to get rid of sections of the material as the material is transformed.

These techniques are similarly essential and generate elements with high precision and regular high quality. They are respectively: grinding, laser cutting, and exploration. The term "surface coating" describes post-processes after the initial machining phase. Motorcycle Parts New Zealand Specialists. The processes aid boost the general quality of the machined bike parts. Below are the quick introduction, pros and cons of 5 surface area therapy techniques.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing